Introduction

The Vertical Axis Wind Turbine (VAWT) is characterized by its simple construction, affordability, ability to self-start at low wind speeds, and lack of a yaw mechanism. It consistently aligns itself with the direction of the wind. This makes it ideal for generating electricity for residential usage in both rural and urban settings in many countries, particularly in India.

Table of Contents

It is widely acknowledged that there is a sufficient amount of wind available worldwide to meet a significant portion, if not the majority, of humanity’s energy needs, provided that it can be efficiently harnessed on a big scale. An increase in the efficiency of a wind turbine results in higher power generation, hence reducing the reliance on costly and polluting power sources.

The Vertical Axis Wind Turbine (VAWT) has the potential to match the efficiency of present horizontal axis systems, while also offering practicality, simplicity, and a substantially lower cost for construction and maintenance compared to the Horizontal Axis Wind Turbine (HAWT).

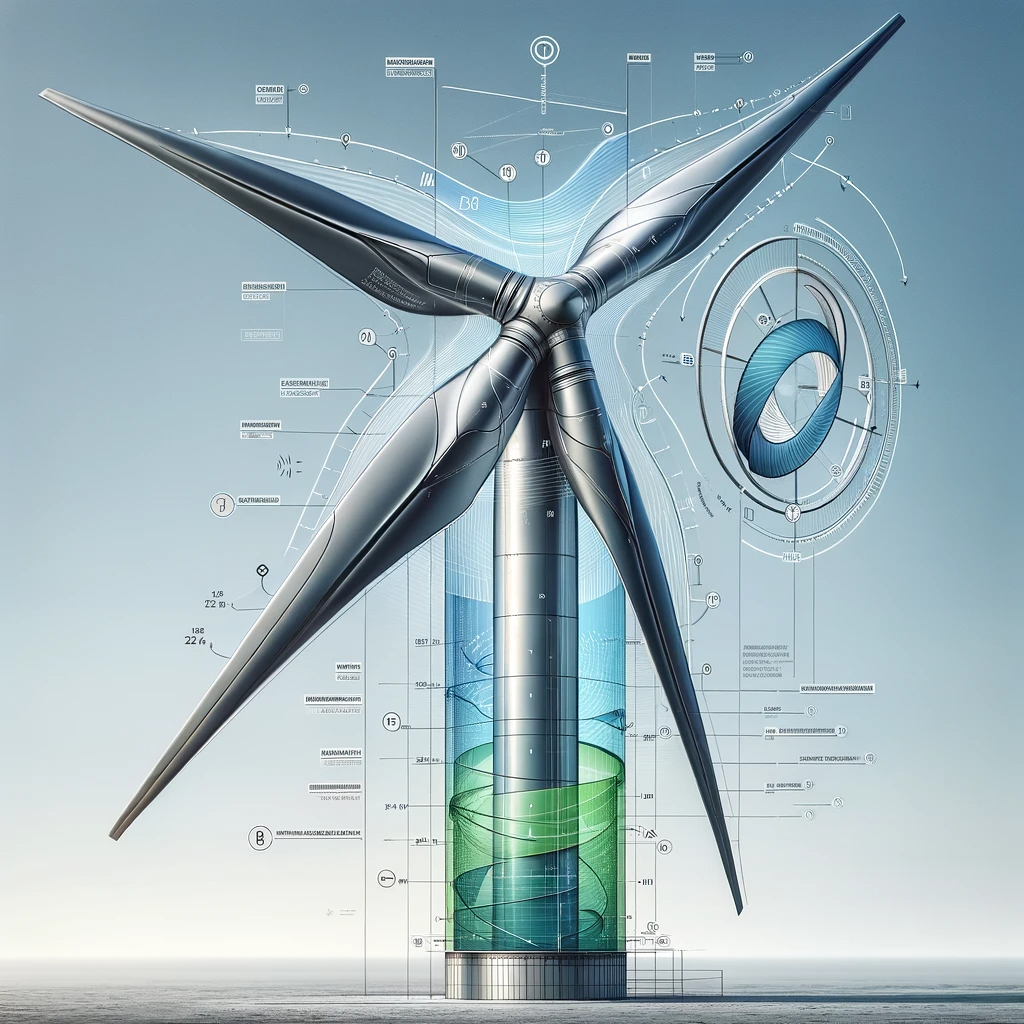

This project involves the fabrication and assembly of a vertical axis wind turbine model, which is equipped with solar panels. The model’s functionality is demonstrated. The fabrication process involves the use of solid works for design and the analysis of the turbine blades. Different materials are selected and analyzed for their suitability.

Aim of the project: Design and analysis of Vertical Axis Wind Turbine

It has additional intrinsic advantages, such as their ability to constantly face the wind, which might potentially position them as a serious contender in our pursuit of more affordable and environmentally friendly renewable electricity sources.

This project aims to analyze and develop a Savonius Vertical axis wind turbine using software interfaces such as SolidWorks and Ansys. The object was analyzed under both static and dynamic loading conditions using three different materials (steel, en-9, al-7075). Real-time boundary conditions were applied to the object. The results for each material were compared using appropriate tables and graphs. Based on this analysis, we can determine which material is most optimal under each set of conditions.

[…] This blog post thoroughly examines Vertical Axis Wind Turbines (VAWTs), investigating its design, benefits, uses, and prospects within the realm of renewable […]