Helical Gears are essential components in the field of mechanical engineering and design, as they are responsible for transmitting power and motion. Helical gears are notable among the several types of gears because of their distinctive design and practical characteristics. This blog post thoroughly examines helical gears, investigating their capabilities, benefits, drawbacks, uses, constraints, and prospects for future implementation in the industry.

Table of Contents

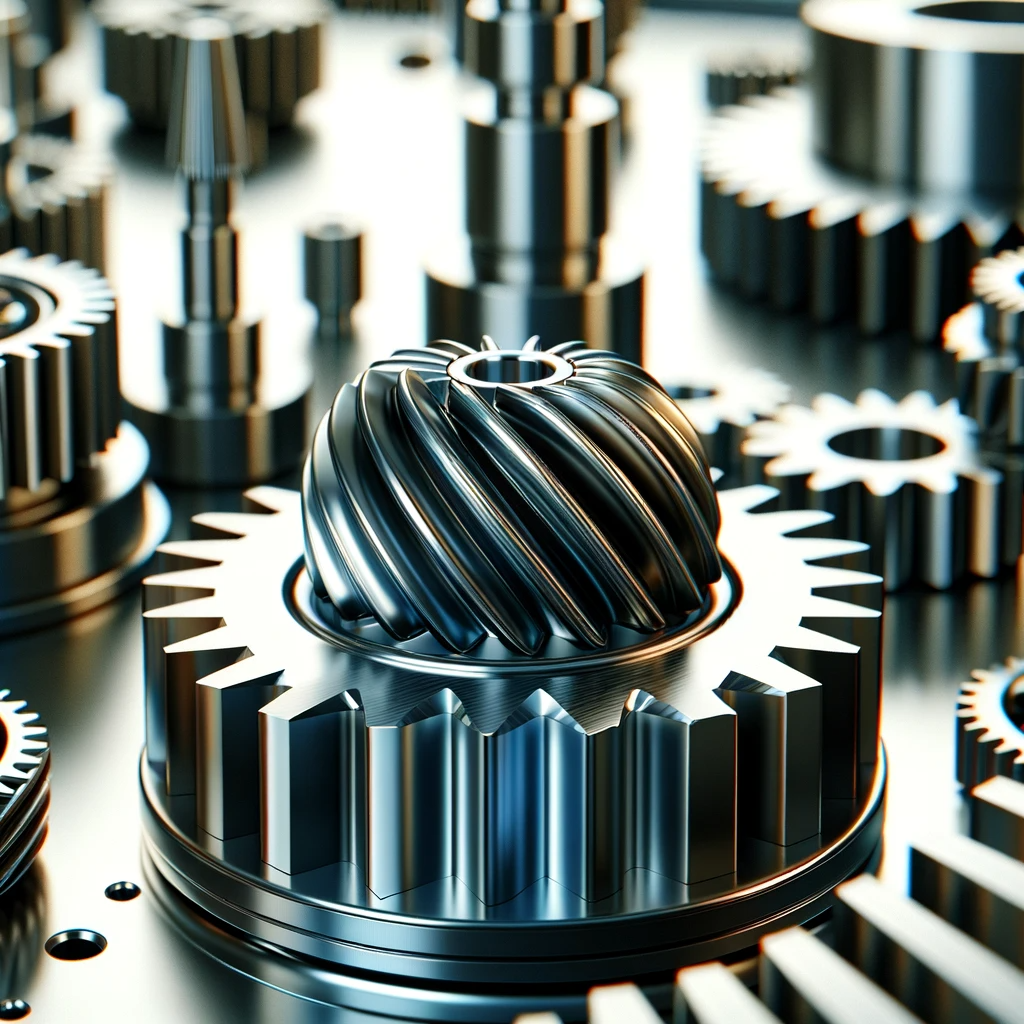

What are Helical Gears

Helical gears are a variety of cylindrical gears that have teeth cut at an inclined angle. Helical gears differ from spur gears in that their teeth are inclined at an angle to the axis of the gear. The oblique technique results in a more gradual interaction between the gear teeth, resulting in a smoother and quieter operation in comparison to spur gears.

Advantages of Helical Gears

- Reduced Noise and Vibration: The angled teeth engage more gradually, reducing noise and vibration, making them ideal for high-speed applications.

- Increased Load Capacity: Due to the overlapping of teeth, helical gears can bear higher loads compared to spur gears.

- Better Durability: The gradual engagement of teeth reduces sudden impacts on the gear teeth, leading to a longer lifespan.

Disadvantages of Helical Gears

- Axial Thrust: The angled teeth generate axial forces, requiring additional bearings to manage these forces.

- Complex Manufacturing: Manufacturing helical gears is more complex and costly compared to straight-cut gears.

- Efficiency Concerns: The sliding contact between teeth can lead to higher friction and slightly lower efficiency.

Applications of Helical Gears

Helical gears find extensive use in various industries due to their smooth operation and durability. Key applications include:

- Automobile Transmissions: For quieter and smoother gear shifts.

- Machinery: In printing presses, conveyors, and blowers.

- High-Speed Applications: In aerospace and high-speed machinery for reduced noise and vibration.

Limitations of Helical Gears

While helical gears offer several advantages, they are not without limitations. These include the need for precise alignment, higher manufacturing costs, and the necessity of complex bearing systems to counteract axial thrust.

Future Scope

The future of helical gears looks promising, with potential advancements in:

- Materials Science: Development of new materials could enhance the strength and efficiency of helical gears.

- Manufacturing Techniques: Advances in 3D printing and precision machining could reduce costs and increase customization options.

- Innovative Designs: Exploring variable helix angles and other design innovations to optimize performance in specific applications.

Add a Comment