Introduction

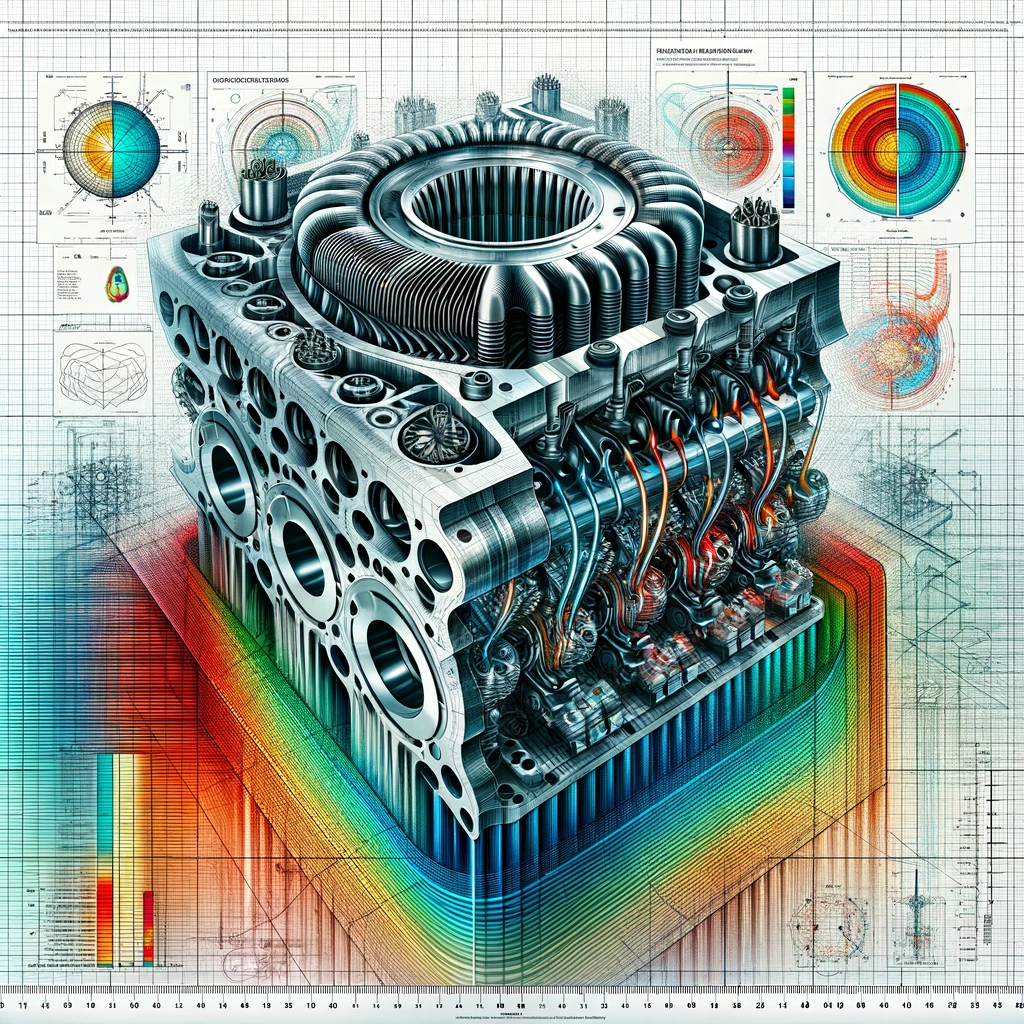

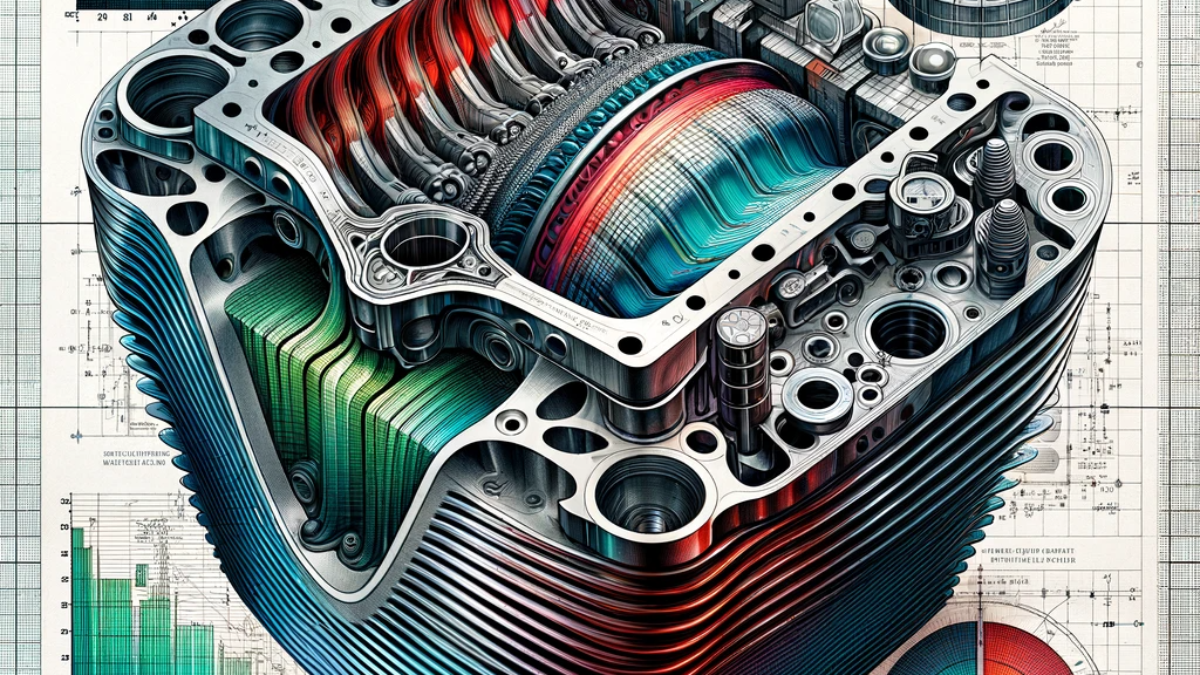

A cylinder head is constructed with a box-shaped part that has significant depth in order to accommodate air and gas passageways, as well as the inlet valve, exhaust valve, and spark plug. The studs or bolts are securely fastened, together with a metal gasket or asbestos packing, to create an airtight connection between the cylinder and cylinder head. The cylinder head experiences elevated temperatures resulting from combustion within the cylinder and pressure exerted on its surface.

Table of Contents

Aim of the project: Static and Thermal Analysis Of V-Shape Cylinder Head

The aim of the project is to design 2 cylinder heads (straight fins and V-shape fins) and analysis is done by using different materials. Cylinder heads are modeled by using SOLID-WORKS software. SOLID-WORKS is a 3d modeling software widely used in the design process. SOLID-WORKS is used by the automotive and aerospace industries for automobile and aircraft product and tooling design

Analysis is done on the models by using different materials. Comparison between materials is done by observing the results of displacement and stress with respect to tables and graphs. Thermal analysis is also done. Analysis is done by using software ANSYS. Here existing material is steel and new materials are (al-6061, cast iron,) by comparing all static thermal results we conclude which material is more optimum in both static and thermal loading conditions.

Add a Comment